Optimized design of molds for injection molding and sustainable

Advanced course organized by TEDFUN

On February 19 DOJE INDUSTRIES , SL He attended the course Advanced Course Design Injection Mold held in Zaragoza organized by TEDFUN and counted with the participation of TECNALIA and company analysis and simulation . The course , aimed at Heads of Production, Quality Technical Staff , Technical Office , production or maintenance was primarily aimed at advanced training for mold design non-ferrous die casting , based on a case study simulation for a piece of aluminum injected.

Defect images tomography

Tomography is a new NDT technology (Non Destructive Testing) to obtain a 3D reconstruction of internal defects. Faults can thus be visualized and quantified with precision (spatial position, area, shape factor, ...).

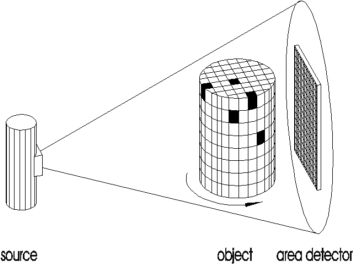

What is the principle of tomography?

Tomography is to use a source radio (microwave hearth) on a workpiece or a sample rotation. The 3D image is then reconstructed by calculation.

Compared to other analysis of internal defects, the tomography means has advantages:

- True 3D image to visualize and diagnose finely internal defects,

- Quantification (Part geometry and defects)

But also imposes constraints:

- Cost of the tool

- Analysis time.

That allows to analyze the CT?

Tomography can do two things:

- From 3D dimensional control room

- From internal health control room

A founder may equip it?

Yes, some have begun to do so for dimensional inspection and health room. Customers or R & D centers are also equipped with a tomograph.

Quantification of internal defects

Micro-tomography, used by IWTC in an R & D has to acquire images with a resolution between 3 microns and 20 microns (1 voxel = 20 mm). Different materials were analyzed (Al Si9Cu3 Al Si12, Al Si17Cu3, zamak, magnesium, ductile iron, aluminum foam). The vast majority concerned the diecasting (Al, Zn) on the draft R & D.

Tomography provides access to the following information:

- Porosity rate (in an area of each)

- Pore diameter (average, min, max)

- Shape factor of pores

- Distance of the pores of the skin piece. This parameter is of crucial importance for the fatigue (in alternating bending, but also to a lesser extent in tension / compression) in the sense that defects very close to the surface initiate fatigue cracks.

However, all these data require an operation manual recount:

- Isolate the area of interest

- Perform a thresholding operation (transformation of an initial gray level image into a black-white binary image). The thresholding operation (image analysis) is clearly the most delicate.

- Erosion and dilation operations that eliminate noise (resulting from thresholding) and too small defects to have a number of pores easily analyzable.

- Analysis of the proper file for realistic rendering and transfer to an Excel spreadsheet.

Image processing

Analysis and quantification of pores

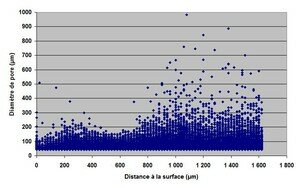

Distance to the surface (pore diameter and the ordinate) for an aluminum part 3.5 mm thick

Pores with respect to the workpiece surface (left and right) part.

Area skin part is relatively healthy.

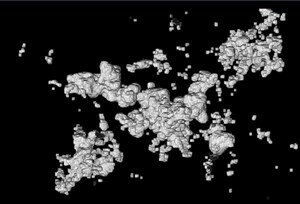

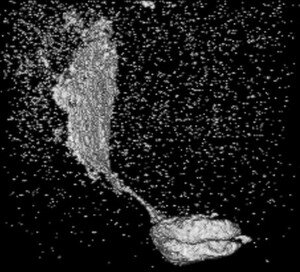

Images of 3D tomography defects

Micro-shrinkage (3D view) - Shrinkage

Recovery (3D view) - Cold shut

Blowhole (3D view) - Blowhole pores

Shrinkage (3D view) without filtering - shrinkage (without erode and dilate operations)

Shrinkage (Al Si9Cu3)

Vídeos

A means of CND future

Tomography is a means of control that begins to emerge from the R & D and is led to the industrial development in the future as to access additional information relative to the fluoroscopy.

Source: My little blog fonderie

The mechanical properties of a casting

A casting, either cast aluminum or steel, has static mechanical properties (Rm, Rp0.2, elongation) and dynamic (fatigue endurance limit) resulting from a number parameters (part design, alloying elements, ..., fineness of the microstructure).

Important factors

The main factors that impact on the mechanical properties (in both static and dynamic) of a part are:

- The content of alloying elements which enter into the chemical composition of the piece (Al-Si7Cu3Mg for an aluminum or 2.7% C, 0.6 Si, 4.2% Ni and 1.6% for Cr cast Ni-Hard)

- The absence of internal and external defects in the parts of mechanically stressed parts. Generally specifies an acceptable level of default (Class 1 for shrinkage in area designated for example) in the room CdC. The impact of defects on the mechanical properties can be understood finely

- The layout of the room (for example the absence of stress concentration areas or isolated solid areas)

- The type of microstructure obtained. For example, the shape of the graphite (flake, spheroidal, vermicular) or matrix (pearlitic, ferritic, austenitic, bainitic) for the font or shape of silicon (lamellar or acicular) or intermetallic compounds (Al-Fe-Si ) for the aluminum alloys

- The fineness of the microstructure (due to the rate of solidification). For some applications, and specifies the DAS (Dendritic Arm Spacing) in microns for aluminum alloys

- Micro-alloying elements in very small amounts (a few ppm to few% versus the traditional alloying elements)

- A subsequent heat treatment that modifies the microstructure (transformation of austenite to martensite in steels for example). For Al-Si alloys, for example, it is the addition of magnesium during the heat treatment allows to increase the mechanical characteristics

- Machining operations that can result in surface pores or cause residual stresses

- Subsequent treatment (local shot peening or hot isostatic pressing, for example)

Source: My little blog fonderie

Aluminum body for the new pickup Ford

Ford stole the show at the last Detroit Auto Show with the new generation of its pick-up F-150 has a body made of aluminum alloy. He said that the new model would weigh between 250 and 320 pounds less than the current, largely thanks to the use of aluminum, and it plans to market at prices close to those of the current (which range from 24 500 à 55 000 dollars). The new F-150 is part of the strategy to reduce the fuel consumption of the manufacturer. Ford has not given any indication on vehicle fuel consumption, but according to reports in the press, he would seek a highway fuel consumption of 7.8 liters per 100 kilometers.

Costs most important materials

The decision to replace the steel body of the most sold in the United States and most profitable Ford by an aluminum body vehicle could revolutionize the U.S. utility market, but also reduce the profits of the manufacturer. It implies higher cost of materials, significant investments in production tools and engineering, as well as the risk of setting complicated and troubled production and possible customer resistance. Also the problem of cost of repairing body panels and in turn the amount of insurance premiums.

Easy repair damaged panels

Ford noted in this regard that the model was designed to be repaired easily. It is also committed to financially assist dealers and repair shops for body panels damaged can be replaced or repaired at a competitive cost. Eric Noble, president of the consulting firm The CarLab, estimated that the use of aluminum would increase the cost of the new F-150 at least 1000 dollars, knowing that aluminum is about three times more expensive than steel.Source: www.ccfa.fr

Source: My little blog fonderie

Filler Video casting machine

Excellent video where you can see step-by-step the filling of a piece of aluminum and plastic at the same time, using a new casting machine.

The foundry institute of RWTH Aachen University presents the new developed hybrid multi-component high pressure die casting process. With this process the possibility is given to manufacture a composite part of two materials (aluminum and plastic) with one tool and one machine.

The silicon foundry alloys

Silicon is the element of controlling almost all alloy aluminum alloys foundry both gravity sand casting and shell (Al Si7Mg0.3 Al Si12, Al Si7Cu3, ...) in die casting pressure (Al Si9Cu3Fe Al Si17Cu3). Silicon is also used in ferrous alloys where it is added in the form of ferrosilicon. There are essentially three qualities of industrial silicon are distinguished by their level of impurity. The metallurgical silicon has a low level of purity while electronic and solar photovoltaic applications require a purity level much higher. Various forms of silicon

THANK YOU FOR YOUR VISIT TO OUR BOOTH AT SUMMIT 2013

DOJE INDUSTRIES S. L. , wishes to thank all the visitors that have come to our booth at SUMMIT 2013 (Bilbao) the days 1, 2, 3 and October 4 and have been interested by our services consists of cast Zamak and aluminum.

We would also like to thank all our customers for letting us share some of their pieces of zamak and aluminum, and also by his visit.

For those who want more information on industries DOJE S. L. , will leave you this link where you can download a Power Point presentation of our activity focused on the production of parts by injection in aluminum alloys and Zamak.

THANK YOU FOR YOUR VISIT TO OUR BOOTH AT SUBCONTRATACIÓN 2015

DOJE INDUSTRIES S. L. , wishes to thank all the visitors that have come to our booth at SUBCONTRATACIÓN 2015 (Bilbao) the days 26, 27, 28, and October 29 and have been interested by our services consists of cast Zamak and aluminum.

We would also like to thank all our customers for letting us share some of their pieces of zamak and aluminum, and also by his visit.

For those who want more information on industries DOJE S. L. , will leave you this link where you can download a Power Point presentation of our activity focused on the production of parts by injection in aluminum alloys and Zamak.

Handling of Aluminum by Goldman Sachs

The North American investment banks Goldman Sachs and JP Morgan are accused of manipulating the price of aluminum by moving their stocks from different warehouses, generating queues in order, longer delivery times, generates premiums for customers wishing to be delivered quickly, which affects the entire market and can artificially inflate the price of the metal.

Several complaints

The complaint stems from a large trans-Atlantic users of aluminum, MillerCoors, a brewer using cans. According to MillerCoors, the aluminum price was inflated by $ 3 billion last year worldwide. Another complaint partnership has been filed in Florida, August 7, accusing the London Metal Exchange (LME), Goldman Sachs, JPMorgan Chase and Glencore Xstrata cartel in aluminum storage.

The technique of suspected fraud

The process is simple because the law requires holders of aluminum to physically go out every day 3,000 tons of their warehouse but it does not say that the aluminum to be delivered. Then just move legally aluminum of a warehouse to another. Goldman Sachs and physically stores of aluminum in 27 warehouses around Detroit. The New York Times, after an investigation revealed that a fleet of trucks will carry a daily aluminum and forth between a warehouse and another. This movement of goods would lengthen delivery times can spend six weeks to over a year. And storage is longer and the invoice to the customer is high for those who want to be delivered quickly pay a premium.

The control of raw materials by banks such as Goldman Sachs' allows them to both predict and influence commodity prices and thus determine the pricing of derivatives and hedge funds in particular on raw materials "says U.S. News.

The role not so clear LME

The LME (London Metal Exchange), which should play a regulatory role in this market is not neutral and is involved because the LME affects 1% of the rental of warehouses and is far from being independent since held until last year by banks with Golman Sachs.

The Fed survey

Given the spate of allegations of fraud, the U.S. central bank (Fed) investigates the physical assets of raw materials held by many banks. In particular it could return to the authorization granted in 2003 to conduct such activities in addition to their sawmills derivatives and commodities brokerage.

Denial of Goldman Sachs

The bank denies any dispute handling and the storage of aluminum can drive up prices. They readily believe, given the reputation of profound honesty that surrounds all of their activities.

Source: www.bfmtv.com

Source: My little blog fonderie