Anodizing of aluminum

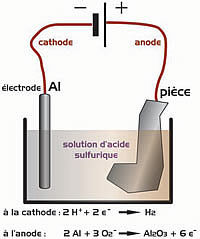

Anodizing of aluminum (or anodic oxidation) is an electrolytic surface treatment can produce a thin protective surface layer and passive microporous alumina (Al2O3) a few tens of microns. The aluminum foundry alloys can all be anodizing treatment.

Principle anodizing SEM anodized layer

What is anodizing?

The functions of anodization are:

- Decoration (many colors)

- The mechanical protection against corrosion, wear (hardness)

- The hanging before painting (not clogged deposit)

- The electrically insulating protective

Handle anodized anodized Lighting

Types of anodizing

There are several types of anodizing:

- Anodizing "hard" in a bath of sulfuric acid (100 microns)

- Chromic Anodizing (a few microns)

- Sulfuric anodizing (10 to 20 microns)

Anodizing decoration (or decorative) can bring a superficial coloration of the aluminum part with pigments (many colors available).

The anodizable alloys

Alloys containing silicon (Al Si family) can be anodization of protection, but are not recommended for decorative anodizing. A high silicon content has a tendency to give a grayish hue. Al MG10 transformed into die casting, provides multiple color decorative anodizing. Al and Al Si2MgTi Mg3Ti (gravity die casting) produce highly decorative colors.

Subset in anodized aluminum pressure

Different thicknesses are achievable anodizing (5 to 50 microns) and depend on the function of the room.

Anodizing operation

The anodizing process consists of a series of bathroom (followed by intermediate rinsing) to prepare a first surface, a second oxide to produce a third color for the potential and the last to stabilize.

Standard

"Specification hard-anodized aluminum and alloys" ISO 10074