Blog (35)

Blog Industrias Doje S.L. - fundición inyectada de zamak y aluminio

Expertos fundidores. Nuestros clientes confían en nosotros. Ya que colaboramos con nuestros conocimientos en fundición inyectada y en la creación de nuevas piezas de zamak y aluminio..

Children categories

Zamak (12)

Árticulos de zamak. Suministra las piezas, de conformidad con los deseos del cliente, parcial ó totalmente terminadas y asesora sobre todos los moldes y útiles necesarios.

View items...

Aluminio (5)

Artículos relacionados con el aluminio. Suministra las piezas, de conformidad con los deseos del cliente, parcial ó totalmente terminadas y asesora sobre todos los moldes y útiles necesarios.

View items...

Actualidad (12)

Actualidad de Industrias Doje S.L. - fundición inyectada de zamak y aluminio

View items...

Fundición inyectada (5)

El moldeo por inyección es una técnica muy popular para la fabricación de artículos muy diferentes.

View items...Ford stole the show at the last Detroit Auto Show with the new generation of its pick-up F-150 has a body made of aluminum alloy. He said that the new model would weigh between 250 and 320 pounds less than the current, largely thanks to the use of aluminum, and it plans to market at prices close to those of the current (which range from 24 500 à 55 000 dollars). The new F-150 is part of the strategy to reduce the fuel consumption of the manufacturer. Ford has not given any indication on vehicle fuel consumption, but according to reports in the press, he would seek a highway fuel consumption of 7.8 liters per 100 kilometers.

Costs most important materials

The decision to replace the steel body of the most sold in the United States and most profitable Ford by an aluminum body vehicle could revolutionize the U.S. utility market, but also reduce the profits of the manufacturer. It implies higher cost of materials, significant investments in production tools and engineering, as well as the risk of setting complicated and troubled production and possible customer resistance. Also the problem of cost of repairing body panels and in turn the amount of insurance premiums.

Easy repair damaged panels

Ford noted in this regard that the model was designed to be repaired easily. It is also committed to financially assist dealers and repair shops for body panels damaged can be replaced or repaired at a competitive cost. Eric Noble, president of the consulting firm The CarLab, estimated that the use of aluminum would increase the cost of the new F-150 at least 1000 dollars, knowing that aluminum is about three times more expensive than steel.Source: www.ccfa.fr

Source: My little blog fonderie

IRILUR S. L. - Lamps and accessories for lamps, has once again put its trust in us to create and merge their new closed arms for luminaire in zamak. After months of work we can say that their new design is ready to be added to IRILUR`s catalog of products.

Unlike the majority of companies of lamps or accessories for lamps, IRILUR S. L. takes you from the years 80 using the zinc alloy "zamak", applied with success to manufacture their lighting products, obtaining forms and geometries not possible with other materials with the exception of the plastics, And by another dramatic improvements of surface finish due to its dimensional stability and smoothness to the obtainable in the surfaces, by deleting processes of filing and polishing that fatally entered, in the brass castings and bronze, and to a lesser proportion in the bilberry, controllable little variations of the originally projected forms (especially in edges and curves of small radio). This protection is obtained either with organic coatings (paints, varnishes, lacquers and enamels) or by electrolytic coatings that, in the brasses are generally of nickel and chrome, and in the case of zamak tend to be copper-nickel-chrome.

Neither must we forget the possibility that has the zamak, like the other metals and certain plastics, coatings to incorporate the tribology of PVD (Physical Vapor Deposition), CVD (Chemical Vapor Deposition) or of PECVD (enhaced Plasma Chemical Vapor Deposition) or The most recent on the basis of nickel alloys and tungsten, which in certain cases are substituting or substituted for the coatings to electrolytic nickel base and chrome that, among the other characteristics do not affect the environment or the health.

A casting, either cast aluminum or steel, has static mechanical properties (Rm, Rp0.2, elongation) and dynamic (fatigue endurance limit) resulting from a number parameters (part design, alloying elements, ..., fineness of the microstructure).

Important factors

The main factors that impact on the mechanical properties (in both static and dynamic) of a part are:

- The content of alloying elements which enter into the chemical composition of the piece (Al-Si7Cu3Mg for an aluminum or 2.7% C, 0.6 Si, 4.2% Ni and 1.6% for Cr cast Ni-Hard)

- The absence of internal and external defects in the parts of mechanically stressed parts. Generally specifies an acceptable level of default (Class 1 for shrinkage in area designated for example) in the room CdC. The impact of defects on the mechanical properties can be understood finely

- The layout of the room (for example the absence of stress concentration areas or isolated solid areas)

- The type of microstructure obtained. For example, the shape of the graphite (flake, spheroidal, vermicular) or matrix (pearlitic, ferritic, austenitic, bainitic) for the font or shape of silicon (lamellar or acicular) or intermetallic compounds (Al-Fe-Si ) for the aluminum alloys

- The fineness of the microstructure (due to the rate of solidification). For some applications, and specifies the DAS (Dendritic Arm Spacing) in microns for aluminum alloys

- Micro-alloying elements in very small amounts (a few ppm to few% versus the traditional alloying elements)

- A subsequent heat treatment that modifies the microstructure (transformation of austenite to martensite in steels for example). For Al-Si alloys, for example, it is the addition of magnesium during the heat treatment allows to increase the mechanical characteristics

- Machining operations that can result in surface pores or cause residual stresses

- Subsequent treatment (local shot peening or hot isostatic pressing, for example)

Source: My little blog fonderie

Tomography is a new NDT technology (Non Destructive Testing) to obtain a 3D reconstruction of internal defects. Faults can thus be visualized and quantified with precision (spatial position, area, shape factor, ...).

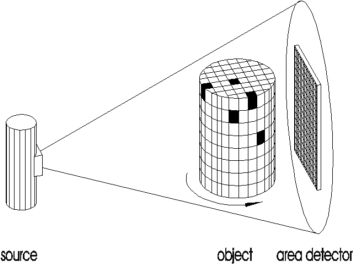

What is the principle of tomography?

Tomography is to use a source radio (microwave hearth) on a workpiece or a sample rotation. The 3D image is then reconstructed by calculation.

Compared to other analysis of internal defects, the tomography means has advantages:

- True 3D image to visualize and diagnose finely internal defects,

- Quantification (Part geometry and defects)

But also imposes constraints:

- Cost of the tool

- Analysis time.

That allows to analyze the CT?

Tomography can do two things:

- From 3D dimensional control room

- From internal health control room

A founder may equip it?

Yes, some have begun to do so for dimensional inspection and health room. Customers or R & D centers are also equipped with a tomograph.

Quantification of internal defects

Micro-tomography, used by IWTC in an R & D has to acquire images with a resolution between 3 microns and 20 microns (1 voxel = 20 mm). Different materials were analyzed (Al Si9Cu3 Al Si12, Al Si17Cu3, zamak, magnesium, ductile iron, aluminum foam). The vast majority concerned the diecasting (Al, Zn) on the draft R & D.

Tomography provides access to the following information:

- Porosity rate (in an area of each)

- Pore diameter (average, min, max)

- Shape factor of pores

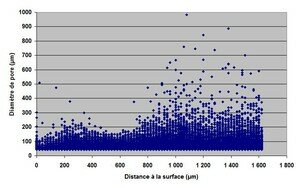

- Distance of the pores of the skin piece. This parameter is of crucial importance for the fatigue (in alternating bending, but also to a lesser extent in tension / compression) in the sense that defects very close to the surface initiate fatigue cracks.

However, all these data require an operation manual recount:

- Isolate the area of interest

- Perform a thresholding operation (transformation of an initial gray level image into a black-white binary image). The thresholding operation (image analysis) is clearly the most delicate.

- Erosion and dilation operations that eliminate noise (resulting from thresholding) and too small defects to have a number of pores easily analyzable.

- Analysis of the proper file for realistic rendering and transfer to an Excel spreadsheet.

Image processing

Analysis and quantification of pores

Distance to the surface (pore diameter and the ordinate) for an aluminum part 3.5 mm thick

Pores with respect to the workpiece surface (left and right) part.

Area skin part is relatively healthy.

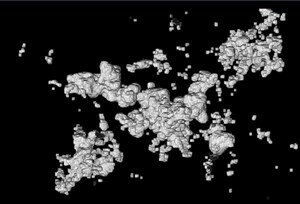

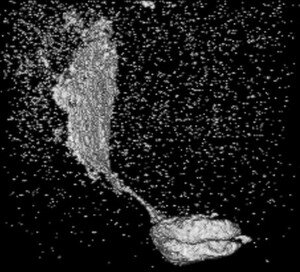

Images of 3D tomography defects

Micro-shrinkage (3D view) - Shrinkage

Recovery (3D view) - Cold shut

Blowhole (3D view) - Blowhole pores

Shrinkage (3D view) without filtering - shrinkage (without erode and dilate operations)

Shrinkage (Al Si9Cu3)

Vídeos

A means of CND future

Tomography is a means of control that begins to emerge from the R & D and is led to the industrial development in the future as to access additional information relative to the fluoroscopy.

Source: My little blog fonderie

From DOJE INDUSTRIES S.L. we want to wish you a Merry Christmas and a happy 2014, full of health, labor and success.